Customer Success

SOFTWARE APPLICATIONS

GEO - Geologists

WellXP - Administrators

WellSTORE - Administrators

INDUSTRY COURSES

Introduction to Data Management

Smart Workflows and Transition Management

Deriving value in IO through Data Analytics

Customer Success

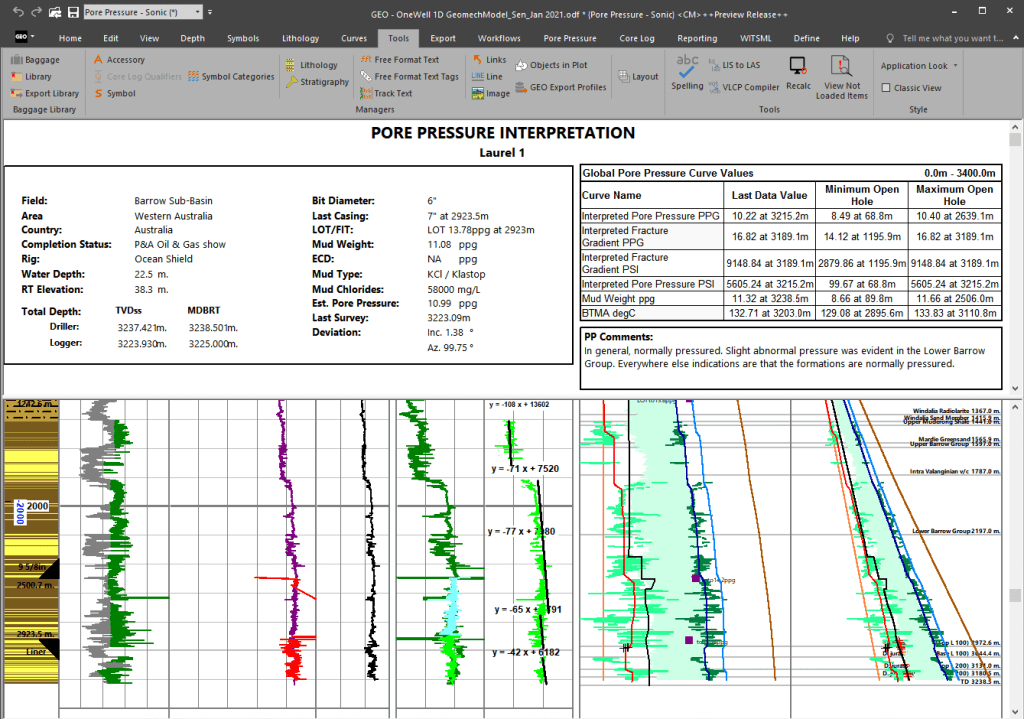

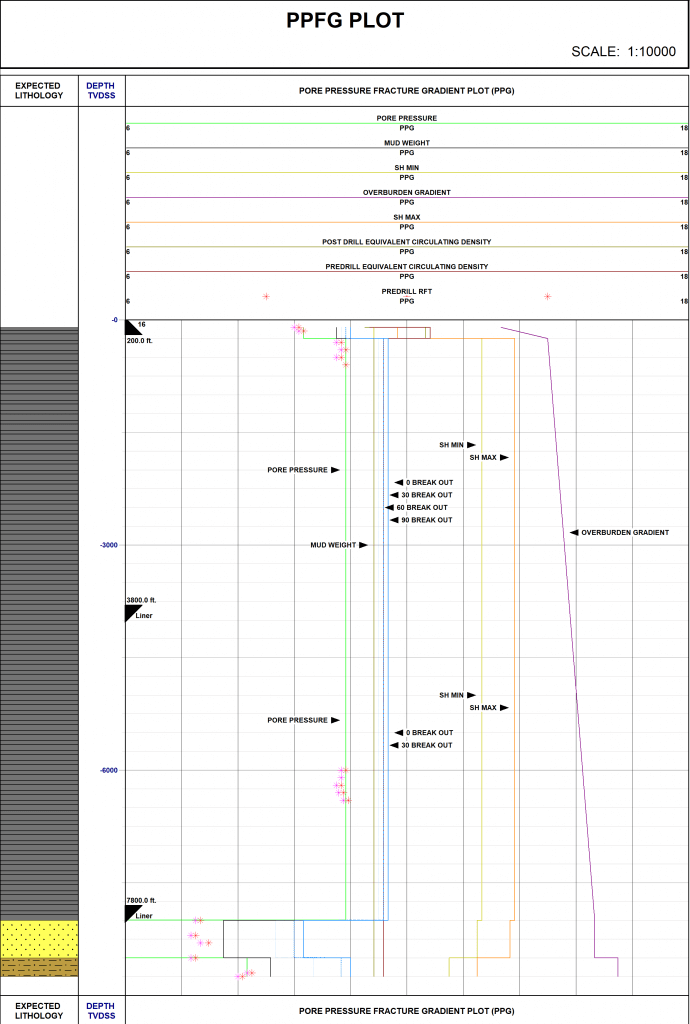

A global, independent UKCS operator, committed to the safe delivery of its wells, deploys effective planning and real-time monitoring of wellbore stability during drilling operations. As part of this, during the planning stage, a specialist geopressure consultancy is used to predict Pore Pressure and Fracture Gradient (PPFG) for the well. This analysis is critical in determining mud weight, hole depth intervals, and pressure transition zones, thus ensuring well safety and successful delivery. The operator then incorporates this data into their well planning and risk mitigation strategy.

The pre-drill geopressure analysis is reformatted into a log that allows the operator’s geoscientists and geologists to manipulate and integrate geopressure data with formation geology and casing architecture. During drilling, this log enables operations geologists to track PPFG and the mud weight window in near real-time.

Initially, this workflow was constructed using a spreadsheet, transposing pre-drill pressure data into pressure-depth cross plots. However, this approach posed several challenges

As a result, the operator sought a more efficient and reliable solution.

Geologix’s Customer Experience Programme fosters engagement with clients, providing opportunities to share workflow challenges and explore new software developments. As a result, Noel Geoghegan, an experienced Operations Geologist, recognised that their spreadsheet-based PPFG workflow, while functional, was placing additional time demands on the team and reducing process efficiency. Proactively seeking a way to enhance this workflow, Noel invited Geologix’s geoscience technicians to analyse opportunities for streamlining and improvement.

Noel and his team were already using Geologix’s GEO Suite software for traditional operations geology tasks. After reviewing the workflow and identifying key bottlenecks, Geologix’s team in Norwich tailored the GEO application to simplify the workflow, reduce complexity, and improve efficiency. With the software already in general use, it was a seamless transition to adopt the enhanced workflow with minimal effort, benefiting from intuitive, purpose-built tools.

A customised template was developed to

Implementing this workflow in GEO had a significant impact on efficiency

By adopting this process within GEO, the operator eliminated the challenges associated with spreadsheet-based workflows. The new approach offers a more robust and easily adoptable solution for future operations teams. Moreover the operator benefits from business continuity through Geologix’s ongoing support services, easily porting the workflow over to new projects and teams.

To learn more about how Geologix can help enhance real-time PPFG insights, increase efficiency and reduce error, request a call with an expert here.