SOFTWARE APPLICATIONS

GEO - Geologists

WellXP - Administrators

WellSTORE - Administrators

INDUSTRY COURSES

Introduction to Data Management

Smart Workflows and Transition Management

Deriving value in IO through Data Analytics

Virtual Reality (VR), Augmented Reality (AR) and Digital Twins

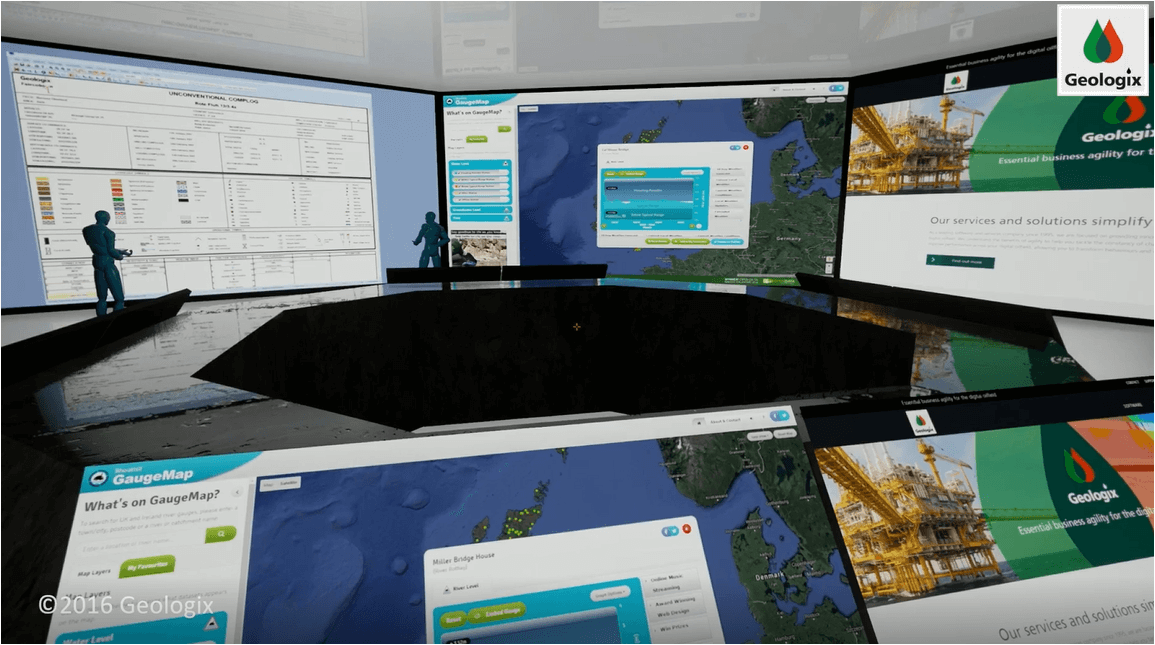

The real strength of VR and AR in oil and gas is their ability to disseminate information to the user in a truly immersive experience. Real-time Operations Centres (RTOCs) are now in widespread use but these suffer from high capital and operating costs, they are difficult and expensive to reconfigure and are often difficult to engage with from a remote location.

Conversely, a Virtual Real-time Operations Centre (vROC) is low cost, can be configured quickly and decommissioned readily when no longer required. With modern networking configurations it is easy to connect from anywhere.

The digital twin links the physical world with the digital (virtual) world, providing a digital model of a physical asset or process. It is the virtual space that the user will navigate in VR and so in the case of a 3D plant model it must represent the physical plant as closely as possible in terms of dimensions and features.

In the case of an existing brown-field plant, the digital twin is constructed typically from a LiDAR survey of the plant, which includes precise measurements and scaling to reproduce the plant as an accurate 3D digital model.

In the case of a pre-build design, the digital twin is usually constructed directly from the 3D design software such as Aveva PDMS.

This picture shows an example of a digital twin including real-time data and trends.

This picture shows an example of a digital twin including real-time data and trends.

Considering the application of VR and AR for immersive visualisation in oil and gas working practices, the main opportunities are in the areas of remote collaboration, visualisation and model/data integration through a digital twin. Example workflows include:

Example of fully animated vROC with real-time information streaming

Example of fully animated vROC with real-time information streamingExploration • Seismic volume reviews • Composite earth model visualisation • Traditional CAVE/HIVE, extending or replacing

Drilling • Well planning • Real-time drilling monitoring • Geosteering planning and monitoring

Reservoir Monitoring • Enhanced recovery monitoring • Water flood monitoring • GOW interface tracking • Drawdown test monitoring in wells • Connectivity and fault leakage testing

Operations • Process and equipment monitoring • Analytics visualisation – equipment and process

Maintenance • Planning and walkthroughs • Real-time impact assessment – hot work – IIoT integration • Support for risk assessment • Work & personnel tracking/monitoring • Training

Decommissioning • Planning • Accessibility modelling / clash detection • Simulation

Value to the Operator

The key value of VR/AR in oil and gas is the delivery of an immersive work environment which provides:

• A virtual mirror of a physical operations centre with remote accessibility

• A low-cost operations centre for smaller assets

• A standard method for remote collaboration

Benefits are delivered through:

• Extending involvement in decision making processes to remote participants

• Providing access to rich immersive data, irrespective of location

• Extending digital transformation workflows to a broader asset base

• Lowering the cost of implementation compared to building a new physical centre

• Configuring dynamically a collaboration space for specific or time dependent needs